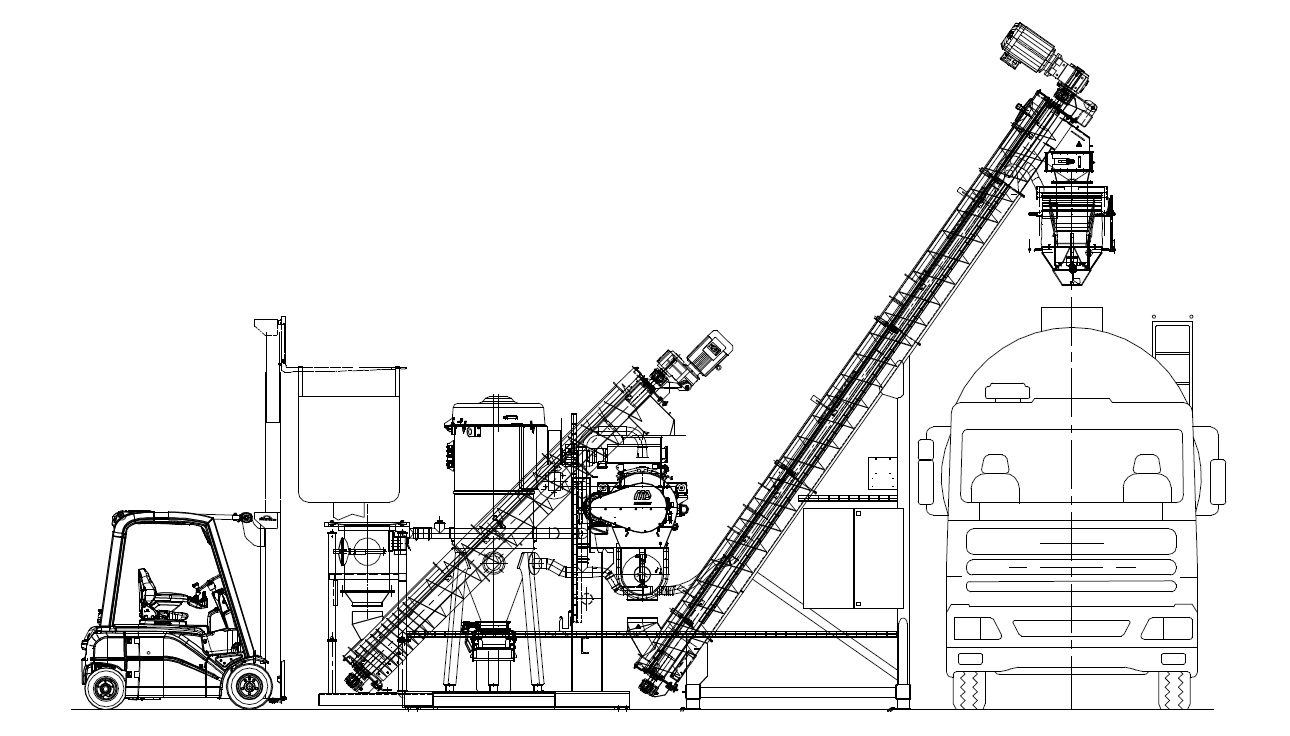

Description Bulk truck loader

Flexible Intermediate Bulk Containers (FIBCs), commonly known as bigbags, are increasingly utilised as a versatile storage and transport solution within the bulk solids handling industry. They provide an efficient means for temporary storage of bulk materials such as starches, powders, and granular products. From storage facilities, these materials are typically conveyed by bulk trucks to customer silo systems.

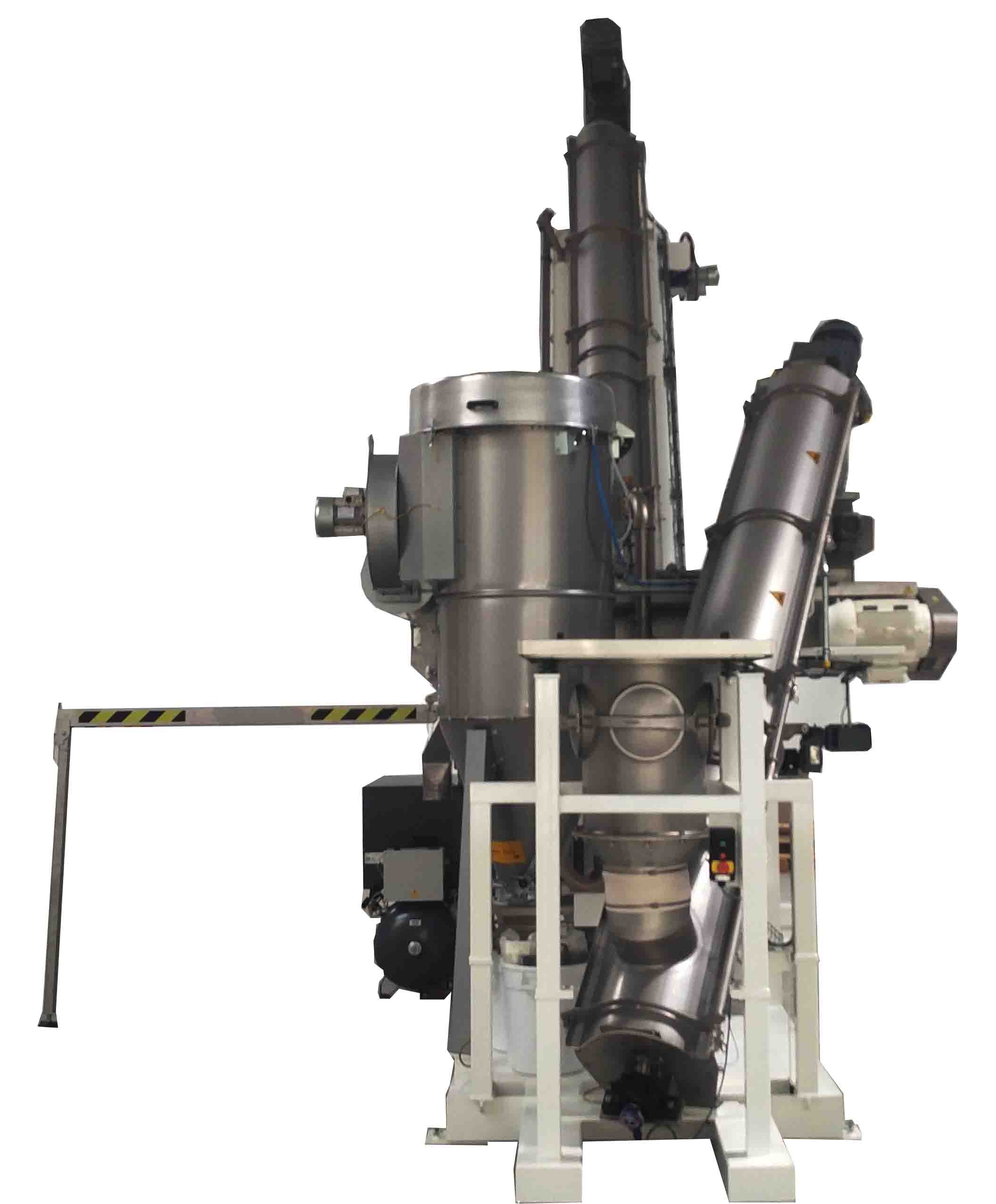

To facilitate the controlled discharge of bigbags and the efficient loading of bulk trucks, Jansen&Heuning has developed the so-called bulk truck loader. This system serves as the interface between temporary storage and bulk transport. The bulk truck loader is characterised by its robust construction and modular configuration, allowing for seamless integration of essential process equipment such as control screens, magnetic separators (de-ironers), and dosing valves.

The installation is suitable for processing a wide range of starches, including native waxy maize starch, potato starch, tapioca starch, and various modified derivatives such as pregelatinised starch or maltodextrins. It is also highly effective for other dust-sensitive or hygroscopic powders, ensuring clean and contamination-free product transfer, thanks to the dust-tight interface and optional dust extraction system.

For applications in the food industry, all product-contact components are manufactured using food-grade materials and conform to Regulation (EC) No. 1935/2004, complete with a Food Contact Materials (FCM) compliance certificate.

The bulk truck loader is compatible with multiple types of FIBC discharge frames (with or without outlet spout) and can be customised with accessories such as vibrating tables, bag cutting systems, or pneumatically actuated valves. The unit is engineered for high operational uptime, essential in continuous and high-throughput bulk processing environments.

Bulk Truck Loader Versions

-

Connection to bulk truck with slab or loading bellows

Provides a dust-tight connection during the truck loading process. Options include a rubber sealing slab or telescopic loading bellows, depending on truck design and required dust suppression level. -

FIBC unloading station with external vibrators

The unloading station is equipped with external vibrators to ensure consistent product flow from the FIBC, especially when handling materials with poor flowability. Forms part of an integrated bigbag handling system. -

Height adjustment for loading with standard trucks

Adjustable-height support frame suitable for standard bulk truck loading or silo inlet connection. Offers operational flexibility and allows for optimal alignment with downstream logistics. -

With or without dust filter (with rotary sluice under filter for dust discharge or dust collector)

Includes an optional integrated dust filter unit, equipped with a rotary airlock (rotary valve) for continuous dust removal to a central extraction line or dust collection bin. Designed to improve air quality and operator safety in dusty environments. -

Suspension frame for FIBC to prevent forklift idle time

A raised suspension frame enables the forklift to be released immediately after FIBC placement, improving internal logistics and minimising equipment downtime. -

Rotating screen for fine control sieving (approx. 300 micron mesh)

Used for the fine screening of powders such as starch, flour, and chemical ingredients. Ensures removal of fine contaminants and complies with food-grade processing standards. -

Steel or stainless steel for product-contact parts

Product-contact components are available in powder-coated carbon steel, stainless steel 304, or stainless steel 316, depending on application-specific hygiene, corrosion resistance, and cleanability requirements. -

Vibrating screen for control sieving (approx. 5 mm mesh)

Enables coarse sieving to remove agglomerates or foreign bodies prior to bulk truck loading. Ideal as a pre-screening step for granular and coarse powdered materials. -

Available with fixed or mobile installation

Offered as either a stationary unit (for permanent installations) or as a mobile version on a steel frame with forklift pockets or wheels. Ideal for flexible deployment across multiple locations or in temporary production setups. -

Other special versions available on request

Custom configurations, including ATEX-certified versions, integrated weighing systems, and CIP-cleanable designs, are available based on project specifications.

Operational Notes

**The stated throughput capacity of the conveyor screws is based on continuous, uninterrupted product supply. Actual capacity may vary due to fluctuations during bigbag handling.

**The maximum allowable FIBC height is determined by the lifting height of the forklift truck and the available overhead clearance.

Contact

For more information or a tailored quotation, please contact Jansen&Heuning:

- Phone: +31(0)50 3126 448

- Email: sales@jh.nl

- Contact form: www.jh.nl/en/contact