Wastewater treatment plant (WWTP) Garmerwolde is the largest WWTP in Northern Netherlands. A by-product of water treatment is sludge cake. This residual product is reused for energy generation. To make the storage and transfer of sludge cake more efficient, a new sludge cake processing station is being built. Jansen&Heuning is the main contractor. The project is being realised in cooperation with Waterschap Noorderzijlvest (client), Utibo (steel construction) and Batenburg (automation).

Phase 1 – Temporary sludge cake processing station

Completion: april 2024

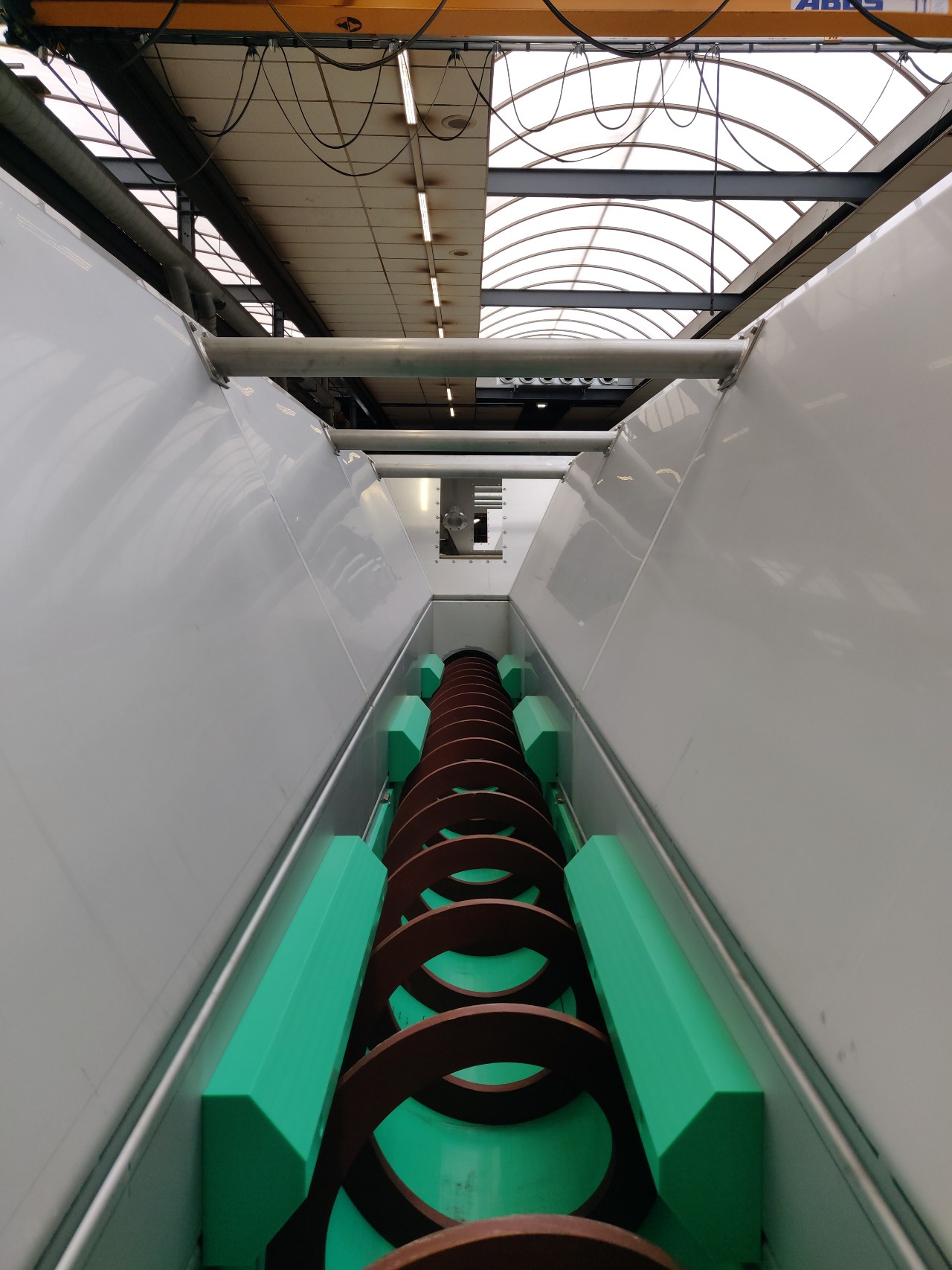

A temporary sludge cake transhipment will first be built at Garmerwolde WWTP, after which the old transhipment can make place for the new one (phase 2). The temporary transfer will eventually remain as an emergency facility. The temporary transfer will allow two trailers to be filled with sludge cake. New shaftless screw conveyors will be used to transport the sludge. The shaftless screw conveyor is ideally suited for the transhipment of rough materials such as sludge cake.

To realise the temporary handling, Jansen&Heuning is building a prefab bypass with two screw conveyors. The existing filling installation and troughs will be dismantled and removed, after which the bypass will be put in place. Meanwhile, new troughs are installed inside. As a final step, all installations will be connected together. The temporary sludge cake transfer will be completed by the end of April 2024.

- Bypass

- Bypass

- Production of shaftless screws

- Temporary sludge cake processing station in operation

- Production of shaftless screws

- Demontage oude stortbakken

- Installation of new troughs

- Installation of new troughs

- Installation of new troughs

- Nieuwe opvangtrechters

Phase 2 – New sludge cake processing station

Oplevering: oktober 2024

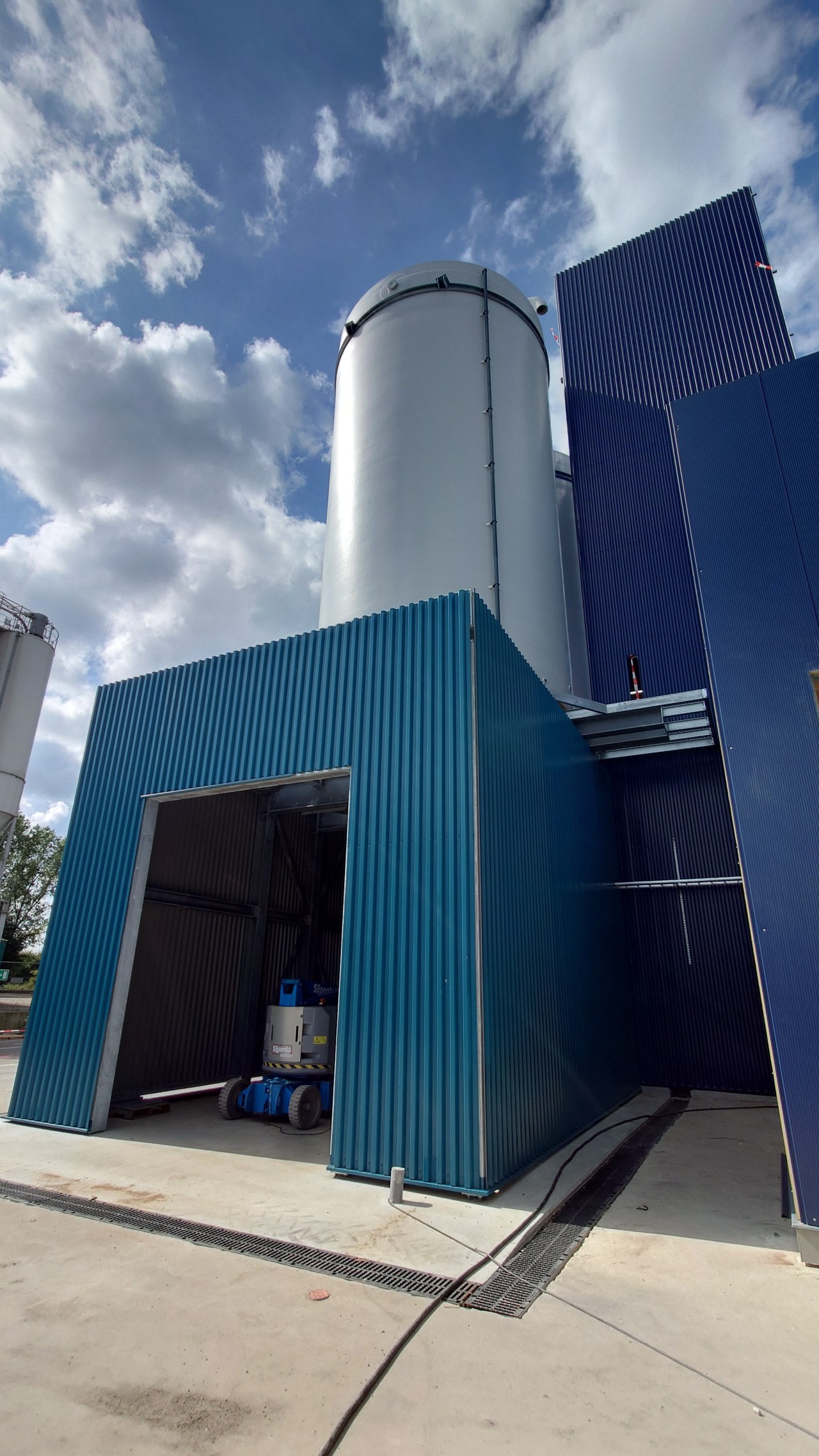

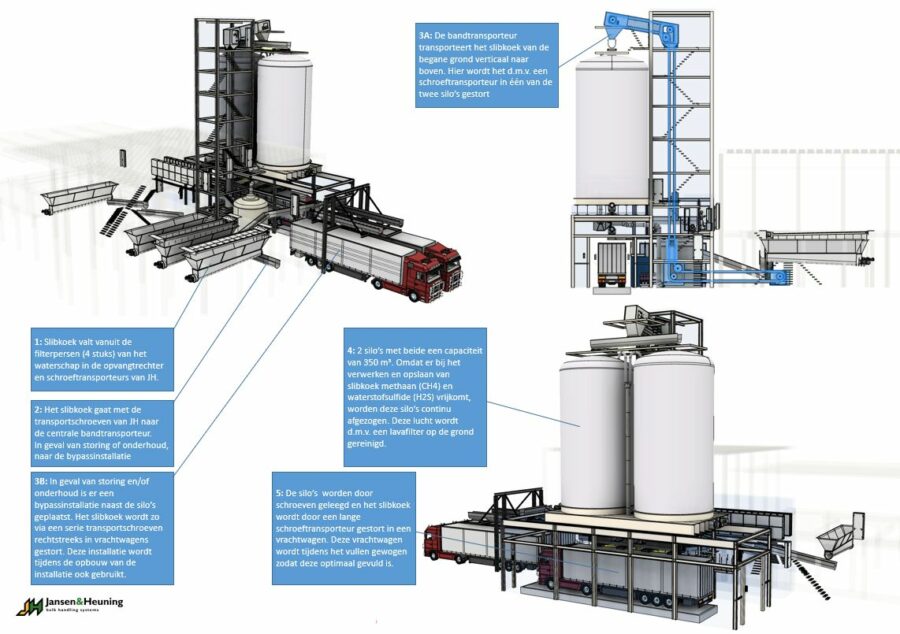

After the temporary sludge cake processing station is in operation, the new, definitive station can also be built. This will include four filter presses, a collection hopper, several screw conveyors, a belt conveyor, two large silos and an extraction system. The picture below explains the full processing process. This phase will start in mid-May and will be completed in early October. Keep an eye on this article and our LinkedIn for live updates!

- Sloop oude fundering

- Storten nieuwe funderingspalen

- Plaatsing weegbrug voor vrachtwagen

- Storten nieuw beton

- Storten nieuw beton

- Plaatsing bandtransporteur

- Plaatsing trappenhuis

- Plaatsing trappenhuis

- Plaatsing silo’s

- Plaatsing silo’s

- Plaatsing silo’s

- Weegbrug

- Wandbeplating

- Elektro

- Bordes voor op de silo’s

- Plaatsen transportband

- Plaatsen transportband

- Plaatsen bordes silo

- Plaatsen bordes silo

Total overview – Sludge cake processing station RWZI Garmerwolde

Result

The new sludge cake processing station is expected to provide energy savings of around 30%. By using silos at height, a lot of space will also be saved. Furthermore, the new working environment is safer for the staff of RWZI Garmerwolde; because closed transport systems prevent employees from coming into contact with the sludge cake. Finally, the loading of trucks is optimal with this innovation sludge cake transfer because trucks can load under the silos and be accurately loaded via a weighbridge.