Description Belt conveyors – heavy duty

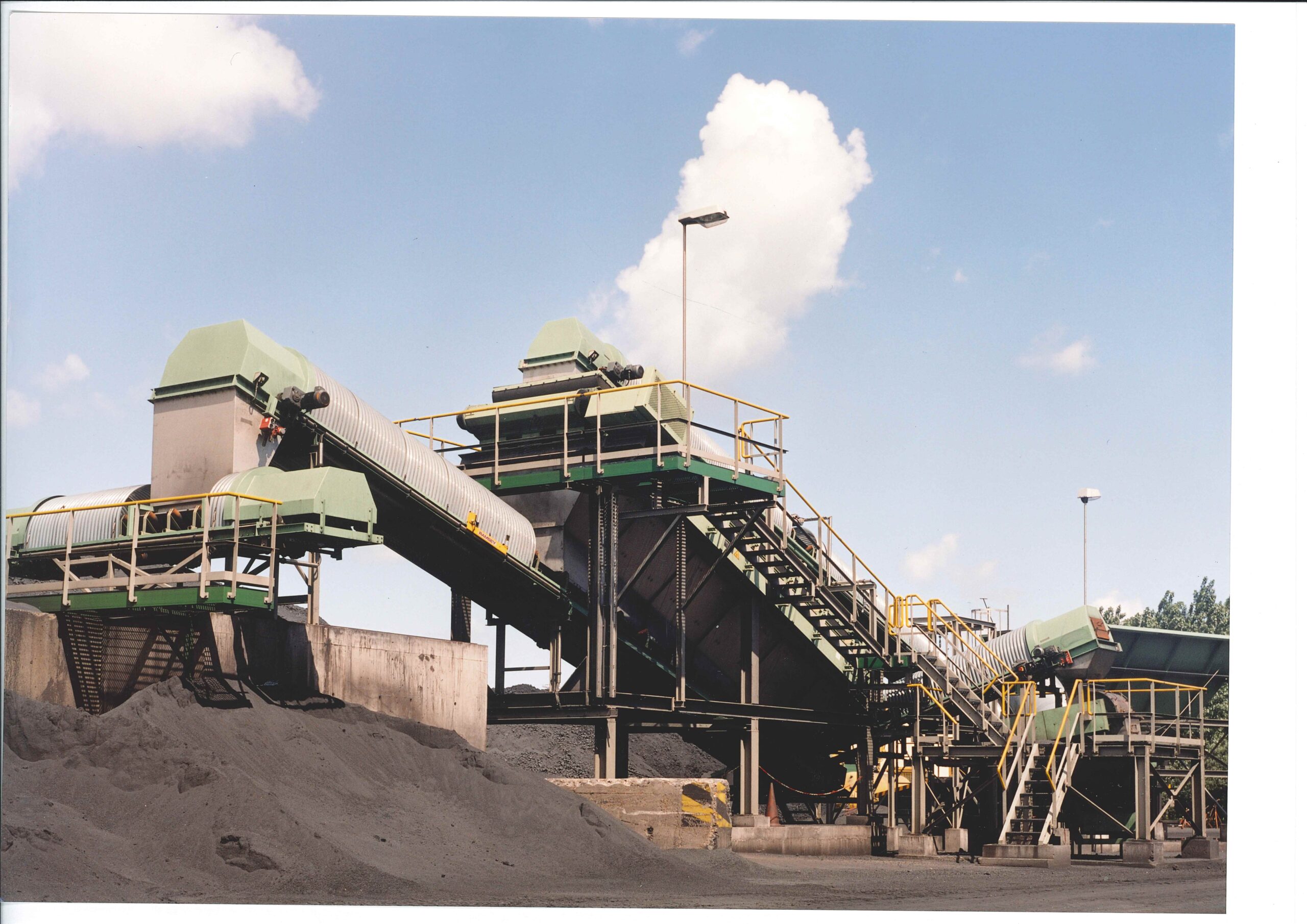

In heavy industry, there are high requirements for operational reliability and long equipment life, especially under heavy loads and challenging environmental conditions. Heavy duty belt conveyors from Jansen&Heuning deliver reliable performance when transporting bulk materials in demanding industrial applications.

Each application has different technical requirements. This is why Jansen&Heuning develops customised solutions in close consultation with the customer. Experience and specific requirements form the basis for the conveyor design. This leads to a solution that is technically compatible with the production process, and guarantees durability, reliability and a long service life under tough conditions.

| Belt width | 500 mm | 650 mm | 800 mm | 1000 mm | 1200 mm | 1400 mm |

| Length drive/reversing roller | 600 | 750 | 950 | 1150 | 1400 | 1600 |

| Frame width (outer dimensions) | 800 | 950 | 1150 | 1350 | 1600 | 1800 |

| Capacity (m³/hour at 1 m/s) | 65 | 115 | 180 | 290 | 515 | 710 |

| all dimensions in mm | ||||||

The JH calculation program enables it possible to independently calculate a complete conveyor system, including the required heavy duty belt conveyor and the supporting steel frame. Technical parameters such as capacity, belt length, inclination angle, material type and belt speed automatically determine the optimum configuration.

The programme not only calculates the correct belt type and the required drive powers, but also takes into account the load on the frame, rolling distances and structural stability. The calculation complies with current standards and is suitable for applications in bulk handling, recycling, heavy industry and storage logistics, among others.

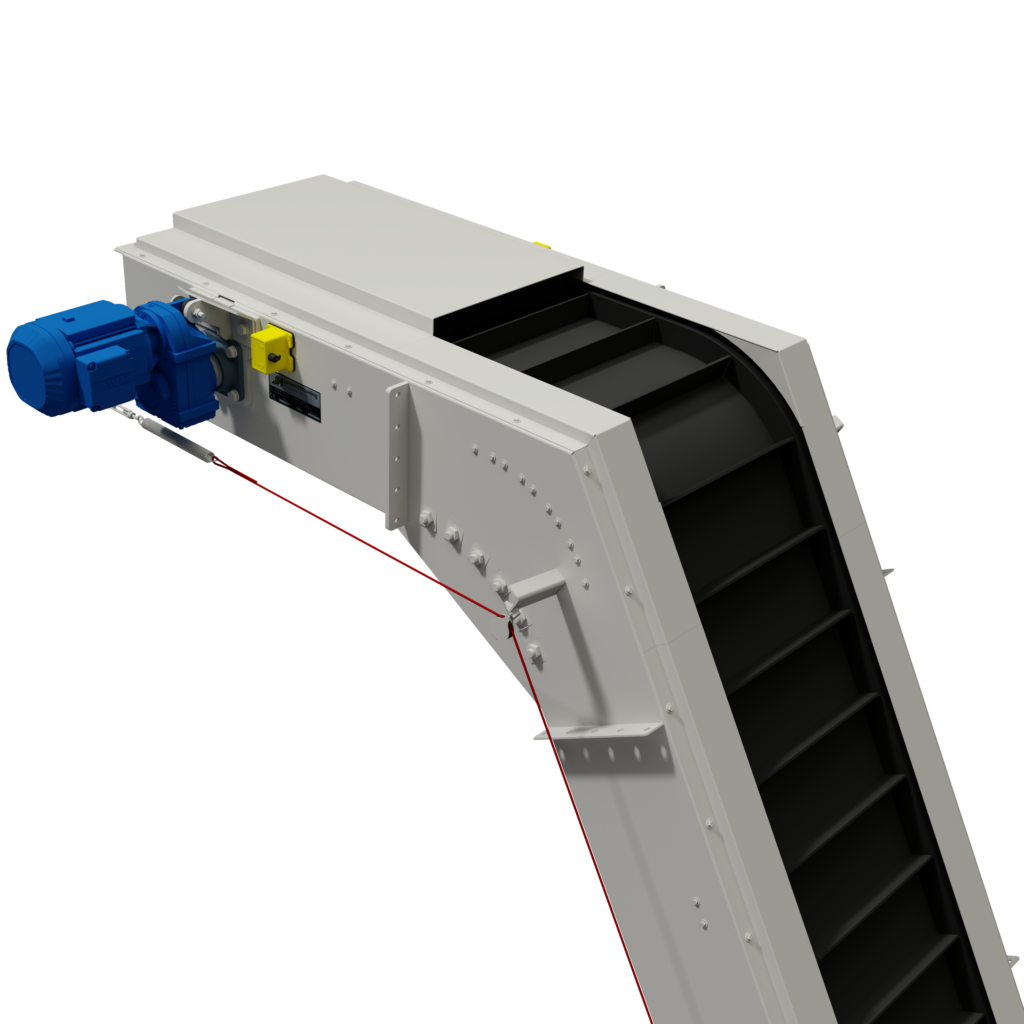

Implementation options Heavy duty conveyor belt

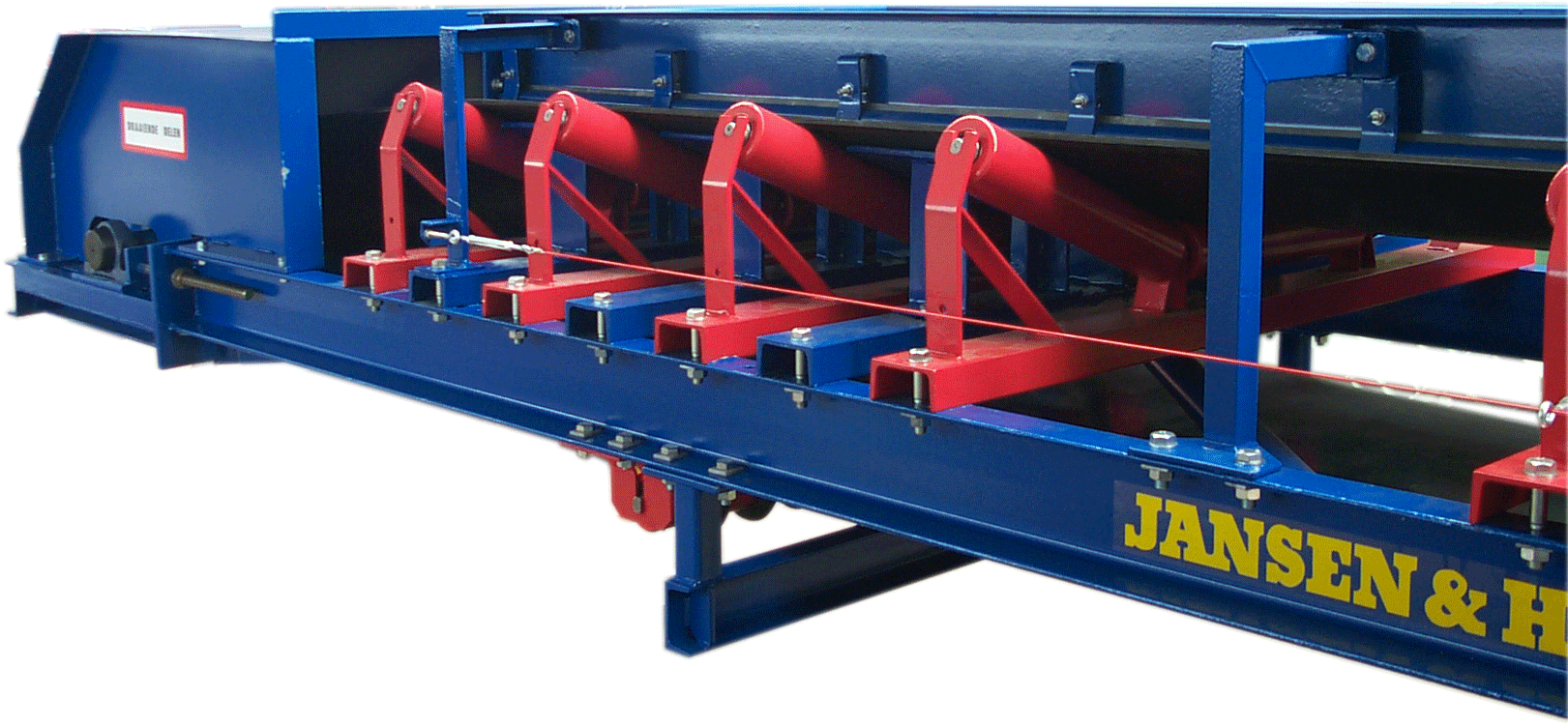

Belt and Belt Cleaning

The conveyor belt in a heavy duty belt conveyor system is made from rubber or PVC, available in several standard industrial grades. Depending on the process requirements, the belt can be equipped with cleats, sidewalls, or lateral guides to ensure controlled transport of bulk materials, particularly under steep inclines or with cohesive materials.

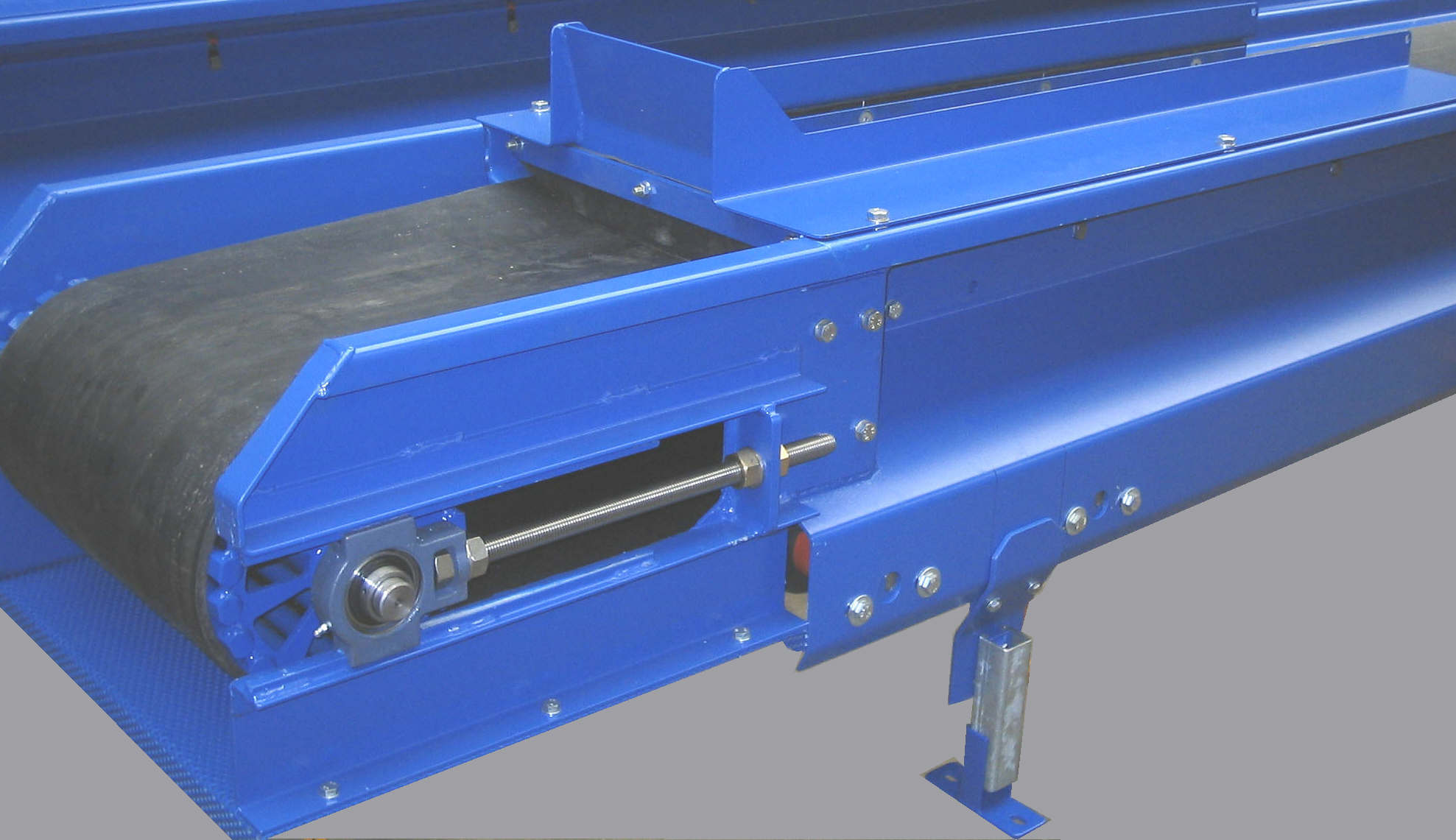

A belt tensioning system using push-type or pull-type spindles maintains correct belt tension at the tail pulley. Alternatively, a gravity take-up unit is suitable for long conveyor runs or applications subject to fluctuating loads.

Effective belt cleaning units are essential to reduce downtime and extend the service life of conveyor components. Internal cleaning employs a plough scraper positioned before the tail pulley to remove residual material from the return side of the belt. External cleaning is handled by a primary or secondary scraper, PU scraper, or rotary brush roller, chosen according to material properties and contamination level.

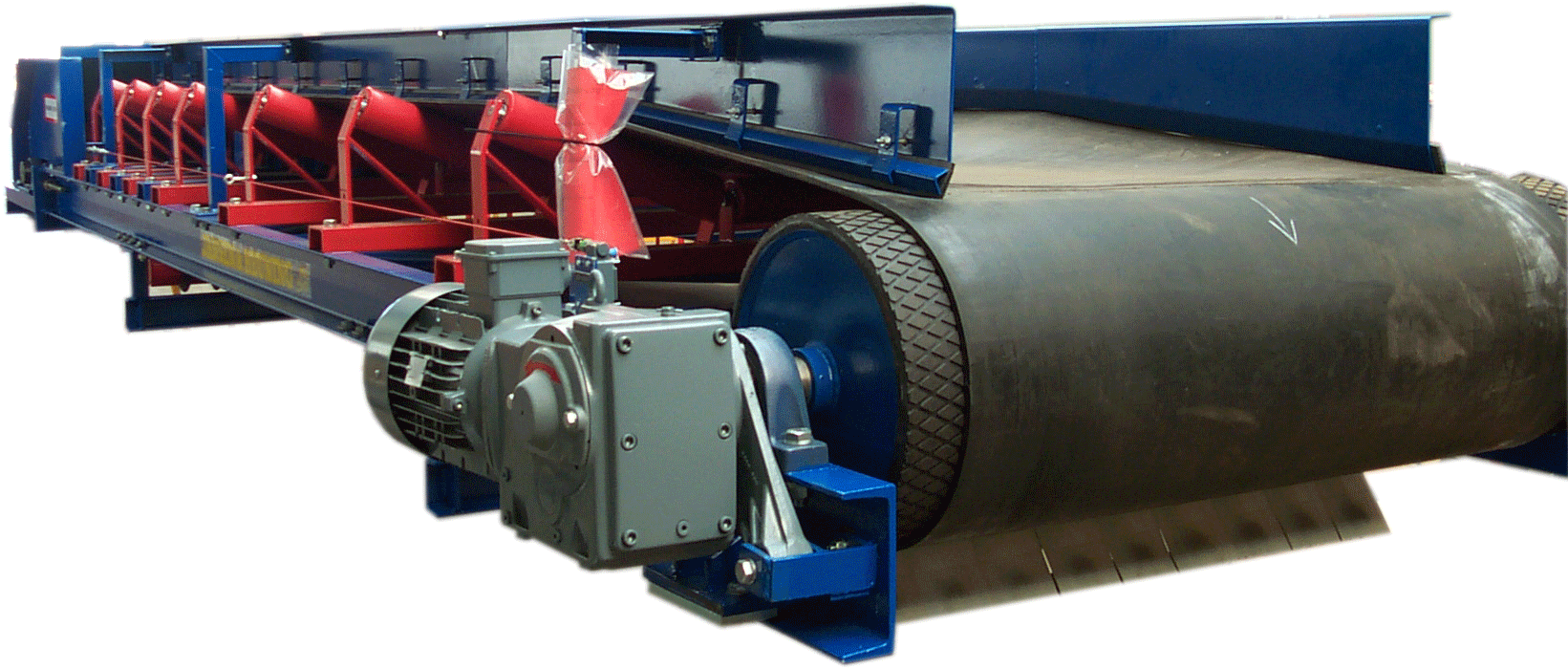

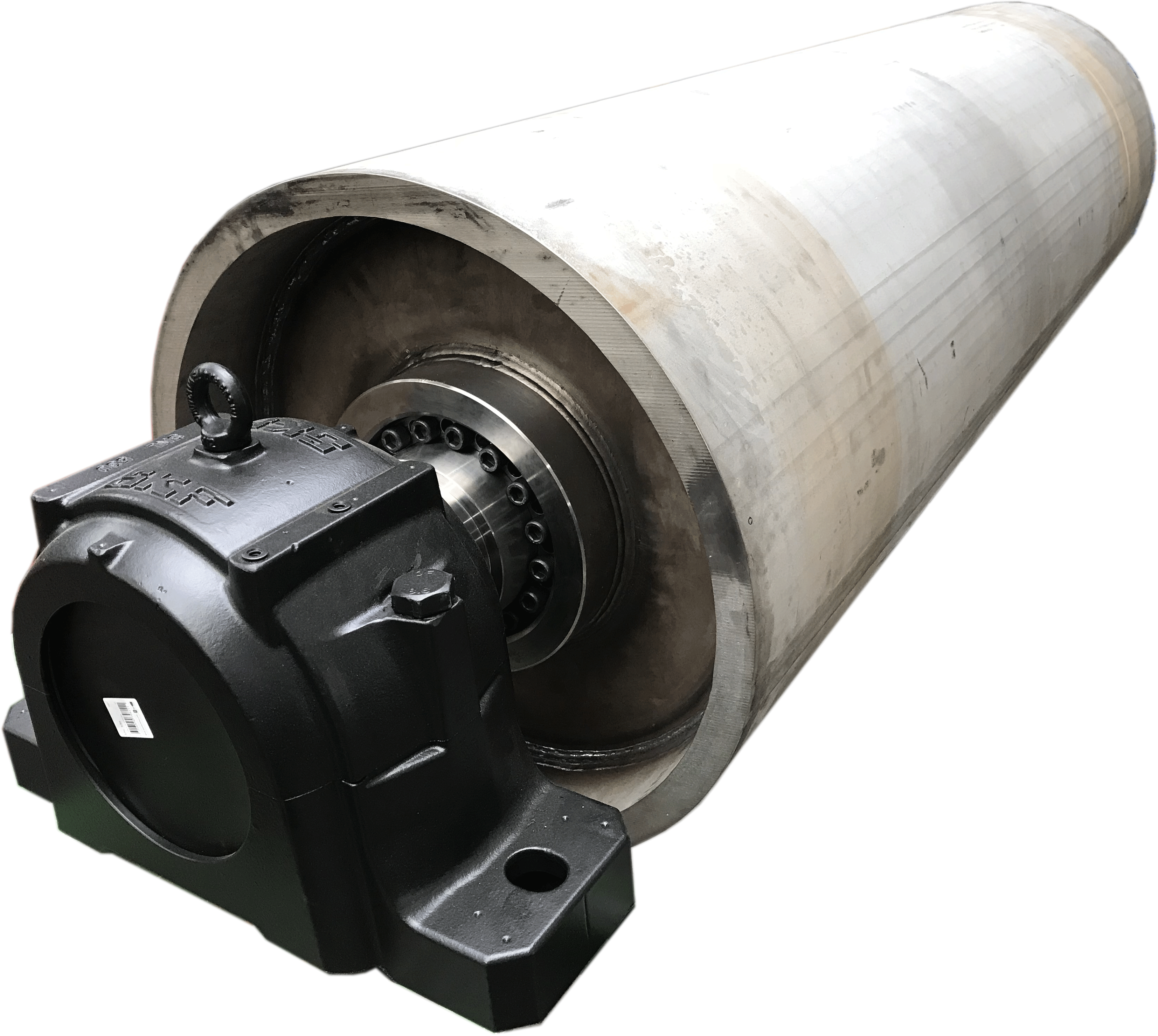

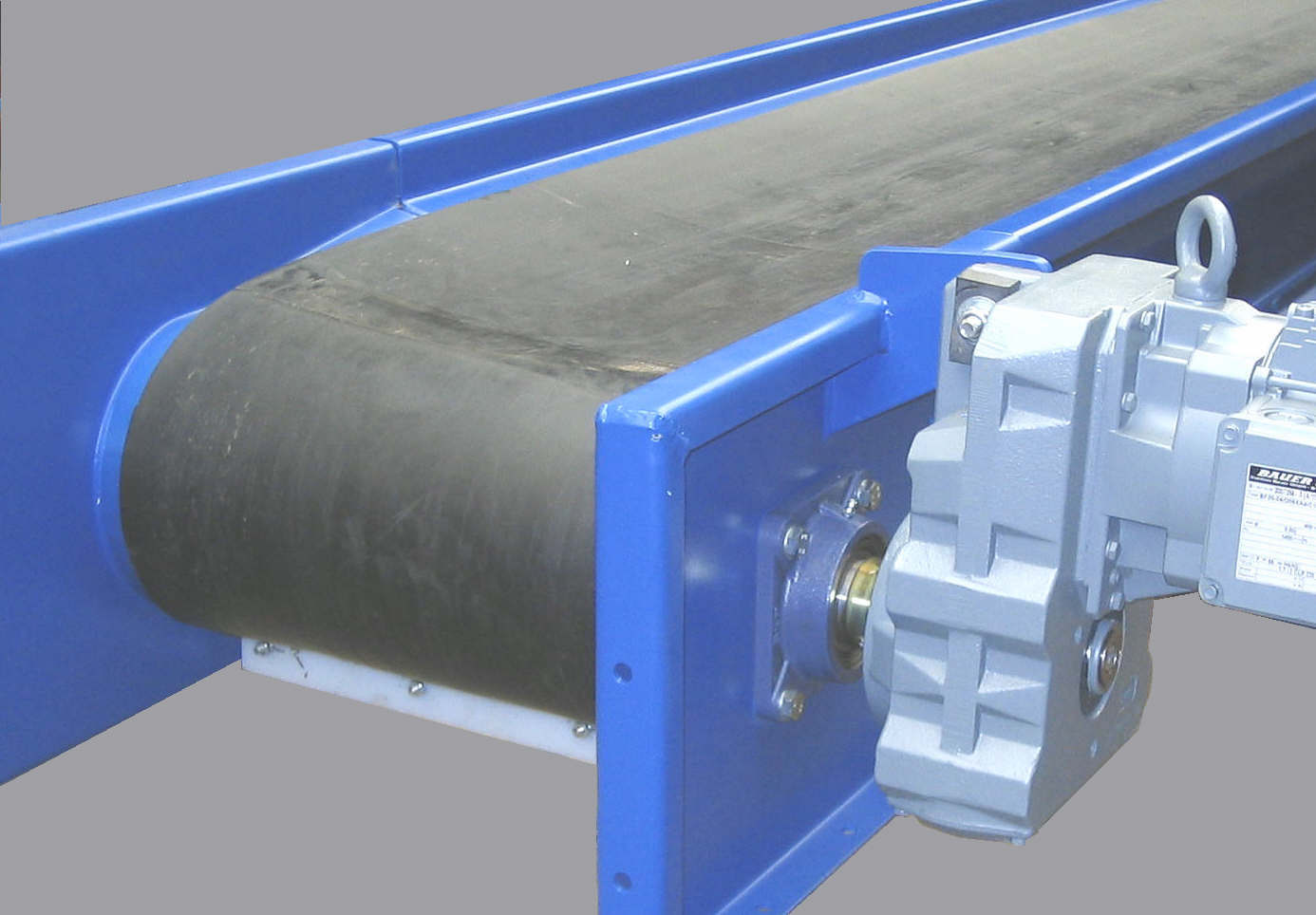

Heavy Duty Belt Conveyor Drive

The conveyor drive system is engineered to match specific capacity requirements, belt speed, and site conditions. Standard drive configurations include an integrated drum motor or a drive pulley with slip-on gearmotor. Both options are designed for high reliability and continuous operation in demanding environments.

Depending on operational requirements, the drive drum may be executed as a sealed steel drum (with or without rubber lagging), cage roller, or vane pulley. These configurations affect belt traction, ease of cleaning, and wear resistance.

Belt speeds of up to 4 m/s are achievable, depending on the transported material, total belt length, and throughput demands. The choice of drive components ensures stable performance, high efficiency, and minimal maintenance, even under severe industrial operating conditions.

Optional

- trough-shaped or flat belt

- roller support or gliding plate

- PVC or bent steel covers

- side guidance dust-tight

- completely closed over the entire length with a simple cleaning installation

- movable

- tripper included

- two conveying directions

Contact

For more information or a tailored quotation, please contact Jansen&Heuning:

- Phone: +31(0)50 3126 448

- Email: sales@jh.nl

- Contact form: www.jh.nl/en/contact