Description Chain conveyor

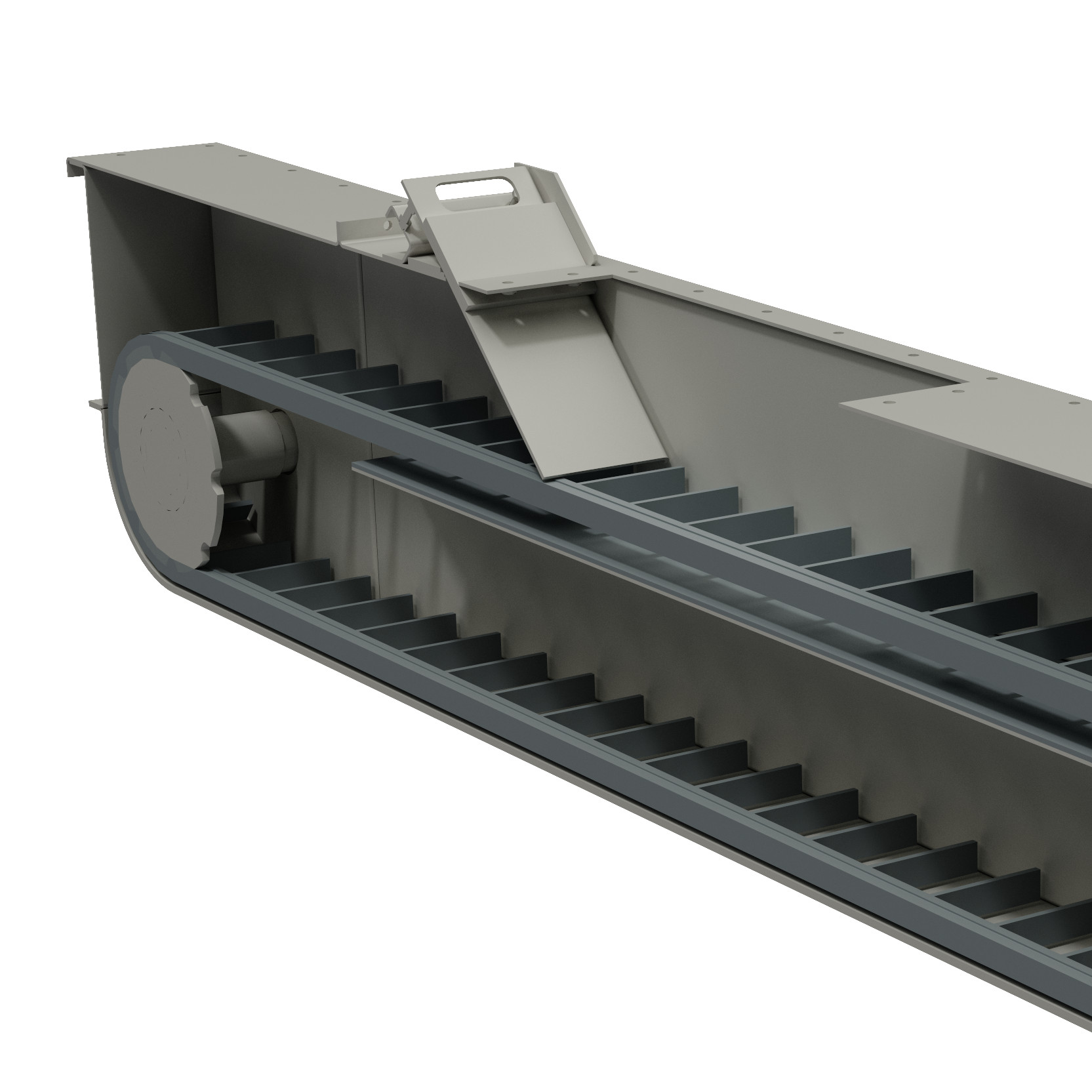

The Jansen&Heuning chain conveyor is a robust and fully enclosed conveying system designed to efficiently transport bulk materials such as powders, granules and food products. By using a chain with extended scrapers, the product is dragged along the bottom of the trough. This system is suitable for both short and long distances.

How a chain conveyor works

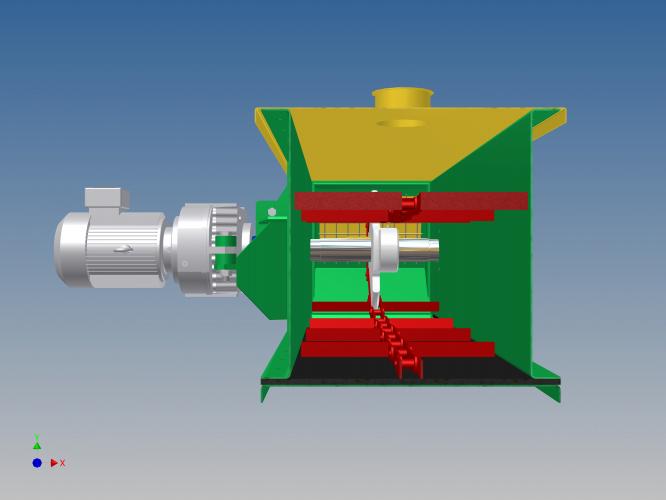

The chain conveyor is driven by a motor that drives a chain with scrapers via a drive shaft. These scrapers pull the product along the bottom of the trough. Thanks to the fully enclosed design, dust emission is minimised, contributing to a clean and safe working environment. In addition, the system is low-maintenance and reliable, resulting in lower operating costs.

Specifications of the chain conveyor

Jansen&Heuning chain conveyors are available in various models, each with specific dimensions and capacities:

| Model | Inner width trough

(mm) |

Outer width trough

g (mm) |

Installation height trough

(mm) |

Length tensioning and drive station

(mm) |

Capacity (m³/h at v = 0.5 m/s) |

| JHK25/26 | 280 | 380 | 450 | 833 | 119 |

| JHK25/39 | 410 | 510 | 450 | 833 | 179 |

| JHK25/50 | 520 | 650 | 450 | 833 | 229 |

| JHK35/39 | 420 | 526 | 576 | 833 | 248 |

| JHK35/50 | 530 | 620 | 576 | 833 | 318 |

| JHK35/60 | 630 | 736 | 576 | 833 | 380 |

Advantages

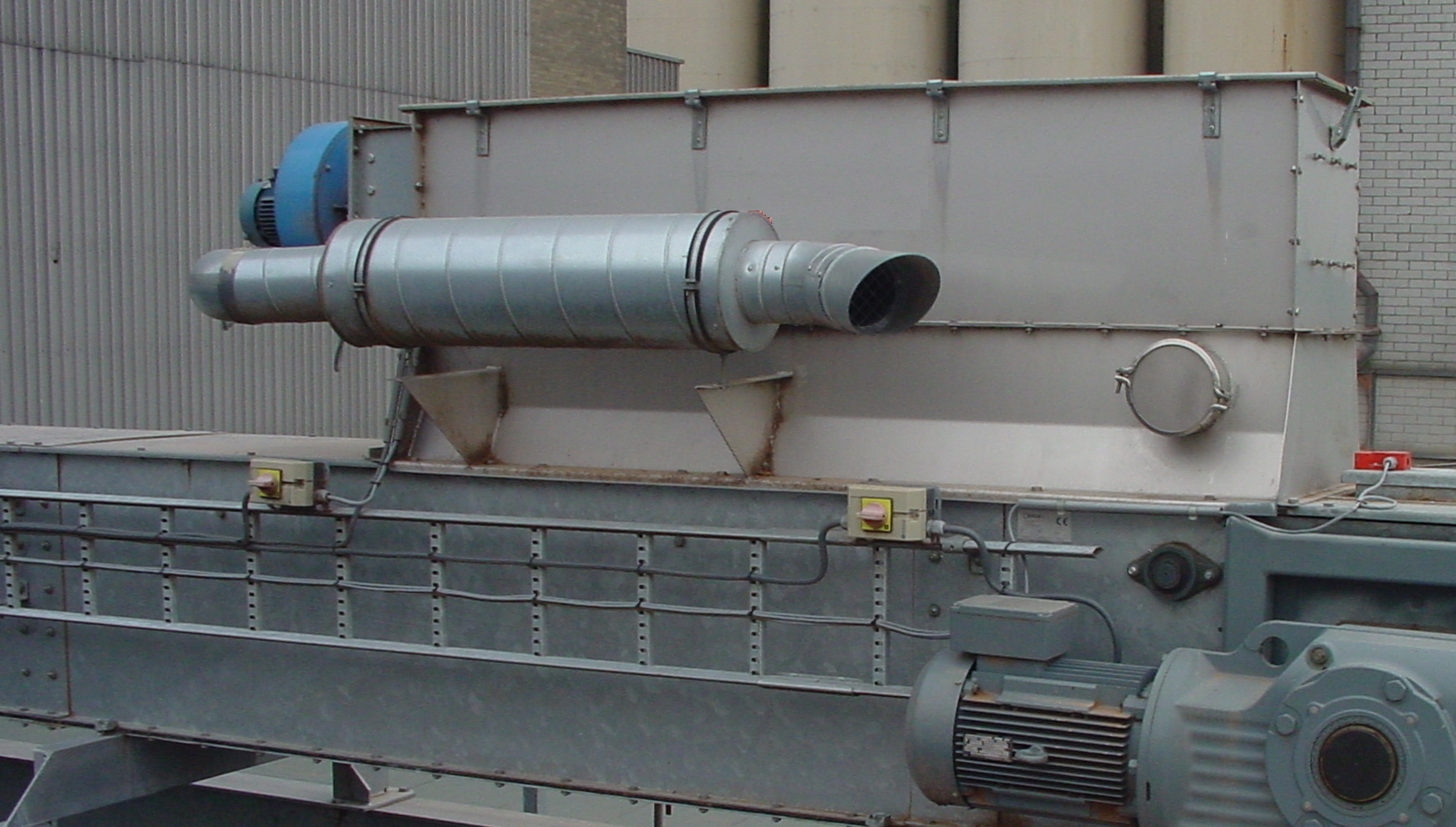

The Jansen&Heuning chain conveyor offers several technical advantages that contribute to efficient and reliable material transport. The system can be used for short and long transport distances, making it suitable for a wide range of installations.

The fully enclosed design prevents dust emissions, ensuring a cleaner working environment and compliance with tighter environmental regulations. In addition, the system requires little maintenance, resulting in lower operating costs and high reliability.

The conveyor can be equipped with various inlets and outlets with manually, electro-pneumatically or electrically operated slides. This allows for accurate product discharge at multiple points within a plant.

Optional

Jansen&Heuning offers various options and customisations for the chain conveyor.

Chain and trough

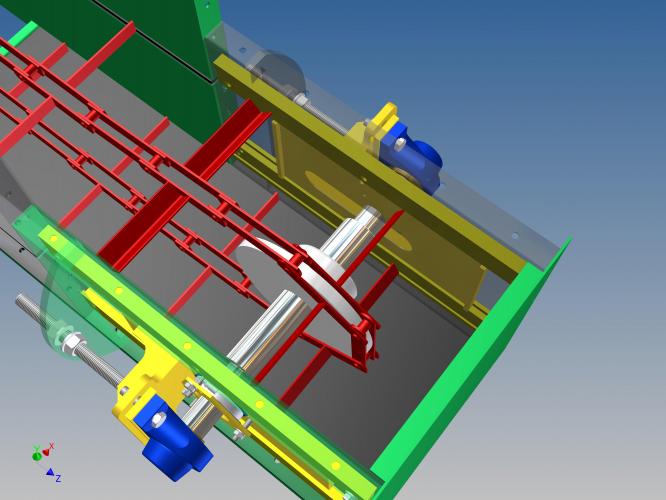

- • Number and type of flights adapted to the product and discharge angle

- • Scraper bars for self-cleaning operation

- • Return cups welded onto the chain for optimal cleaning to the end of the trough

- Trough with plastic bottom or wear strips for a longer service life

- Materials of your choice: St.37, stainless steel, manganese steel, depending on the application

- Tensioning by adjustable axle of the deflection wheel

Inlet and outlet

- Inlet directly or with capacity control slide and intermediate bottom

- Various versions: manual, electro-pneumatic, electric

Versions

- With intermediate bottom for bi-directional transport

- Prepared for speed control on the return wheel

- Overflow protection

Contact

For more information or a customised offer, please contact Jansen&Heuning.

- Phone: +31(0)50 3126 448

- E-mail: sales@jh.nl

- Contact form: www.jh.nl/contact