Description Hammermills

The DM6 hammer mill is a newly developed mill for grinding feed for pigs and poultry. The suply of products to the hammer mill is preferably frequency controlled so that the supply is constant. This has the advantage of optimum utilization of motor power. The discharge can be seperated with a small screw underneath the mill, possibly with a filter for seperate discharge of dust and hot air. The capacity of wheat is up to 4 tons/hour. The advantage of this simple but robust construction is that there is little heat generation during the milling process and replacement of wearing parts is very easy.

Rotor with suction effect up to 4 tons/hour

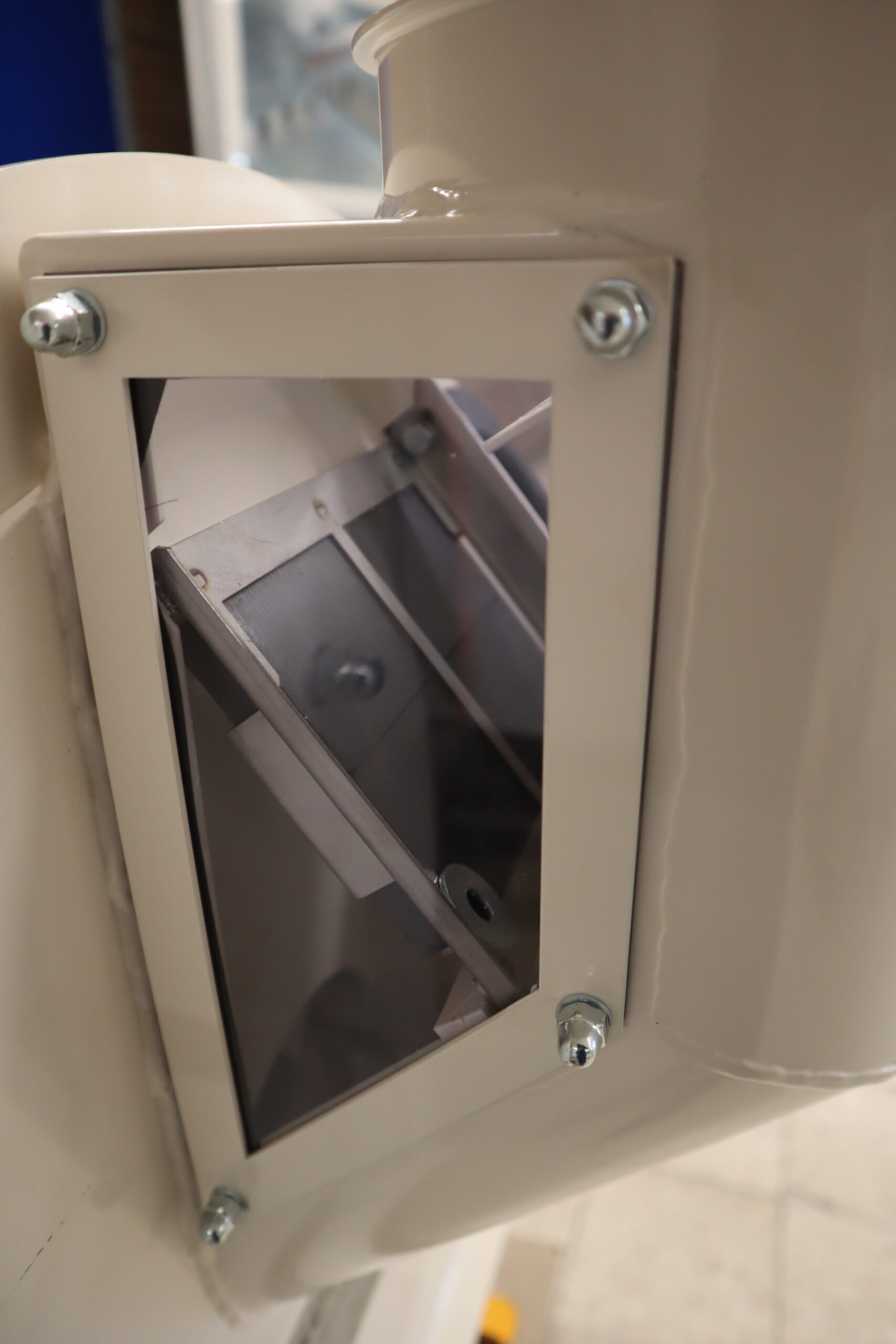

The material is sucked into the center of the rotor where it is evenly distributed on the screen. The mechanical transport to and from the mill. combined with the suction effect, provide the most optimal grinding with low energy consumption and limited heating of the product.

Cooling and dust extraction during the grinding process

When moist and/or very fine materials is being grinded we recommend to provide some airflow within the mill. The air flow provides a cooling and drying effect minimizing dust generation in the mill and the following means of transportation.

The best effect is achieved by applying anactive filter (point filter) to the conveyor just after the mill. The airflow should be 300 to 700 m3/hour depending on the grinding capacity. After finishing the grinding process an ‘after-filter’ is advised for 30 minutes, this is to prevent mold in the mill.

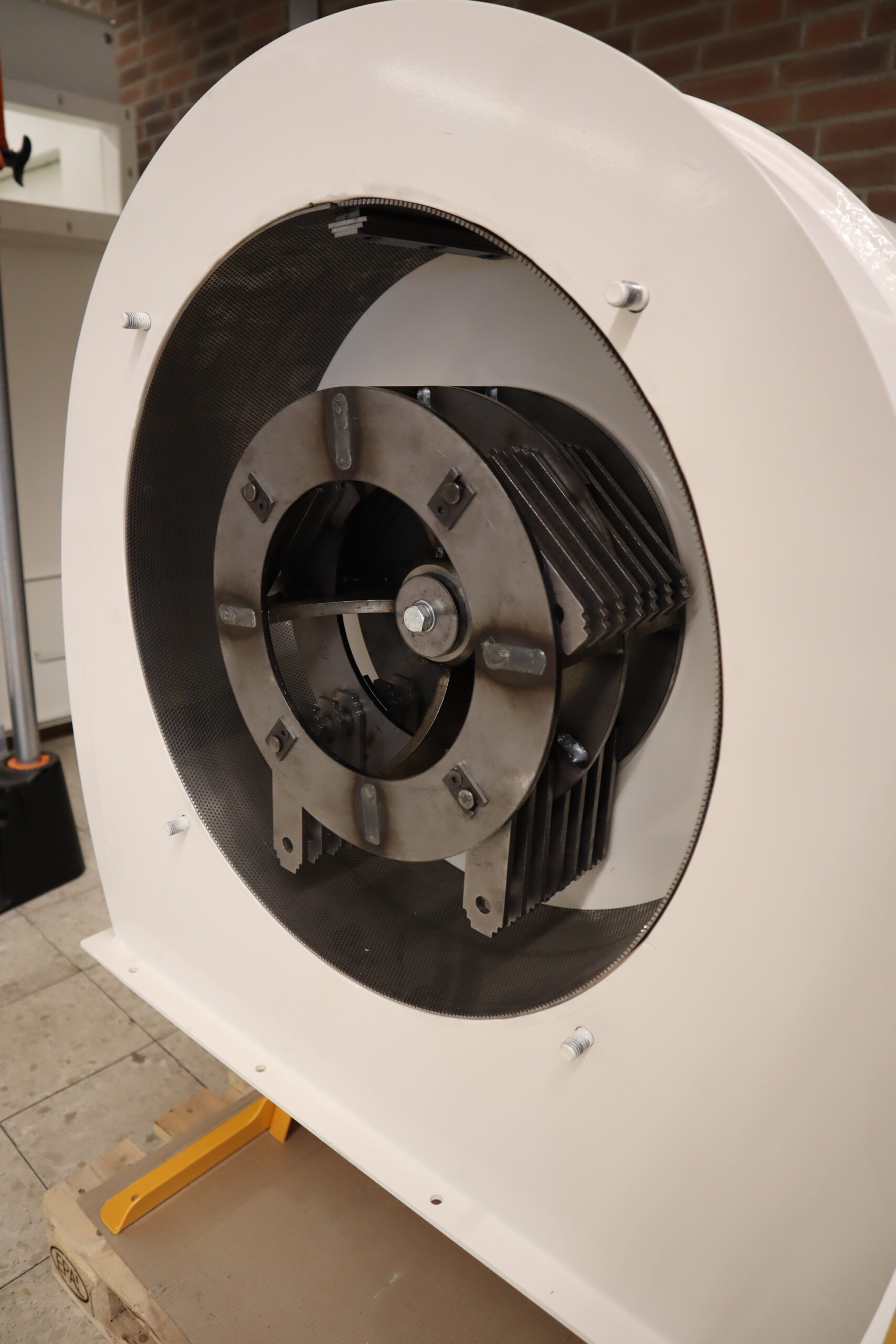

Hammers

The hammers are made of durable, hardend stele and are also available with additional welded-on wear-resistant material. The orignal hammers have a long service life and trouble-free operation; each hammer is extensively checked for quality.

Sieves

The mill is available with two different types of sieves; a wire sieve or a plate sieve. The wire sieve consists of woven steel and gives a slightly higher capacity than the plate sieve. The plate sieve is completely flat and has round holes. The life of a plate sieve is slightly longer than a wire sieve. Capacity depends on sieve size, product and moisture content. The mill in its standard design processes products with a moisture content of up to 20%. Sieve perforations available from Ø1.0 mm to 15×15 mm.

Capacity in kg/u (engine power 7,5 to 22 kW)

The capacities are an indication.

| indication capacity kg/hour | 4,0 mm plate sieve | ||||

| kw | 11 | 15 | 22 | ||

| Barley | 1280 | 1650 | 2300 | ||

| Wheat | 1960 | 2780 | 4200 | ||

| Oats | 610 | 895 | 1400 | ||

| Corn | 2340 | 3420 | 5300 | ||

| indication capacity kg/hour | 3,15 mm wire sieve | ||||

| kw | 11 | 15 | 22 | ||

| Barley | 1880 | 2650 | 4000 | ||

| Wheat | 1960 | 2780 | 4200 | ||

| Oats | 810 | 1170 | 1800 | ||

| Corn | 3050 | 4300 | 6500 | ||

The capacity depends on type of screen, motor, moisture content and product.

| Motor | 11,0 – 15,0 – 22 kW (2800 rpm) |

| Sieve surface | 2.700 cm² |

| Sieve type | plate sieve(Ø) or wire sieve (◊) |

| Amount hammers | 28 |

| Nois level | ca. 85 Db (A) |

| Weight | 205 – 245 – 255 – 270 – 315 kg |

| Capacity | 350 – 6500 kg/h |

The capacity when grinding moist product decreases by 5% each time the moisture content increases by 1%.

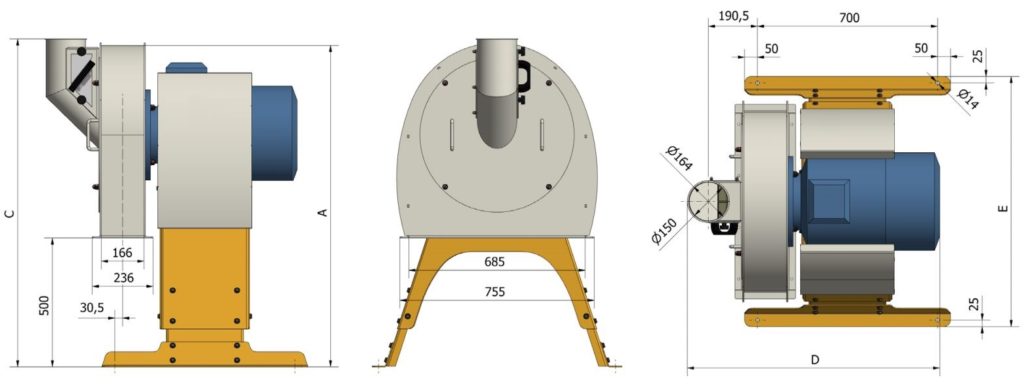

Measurements in mm

| DM6 | A | B | C | D | E |

| 971-1165 | |||||

| 11 kW | 1130-1400 | 480-750 | 1230-1500 | 940 | |

| 15 kW | |||||

| 22 kW | 1150-1400 | 500-750 | 1250-1500 | 1025 |