Description Seed cleaner

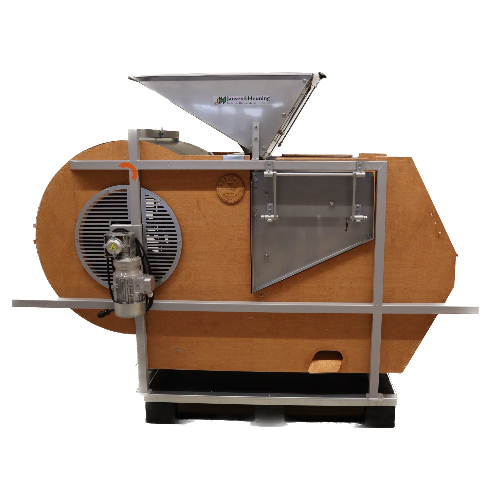

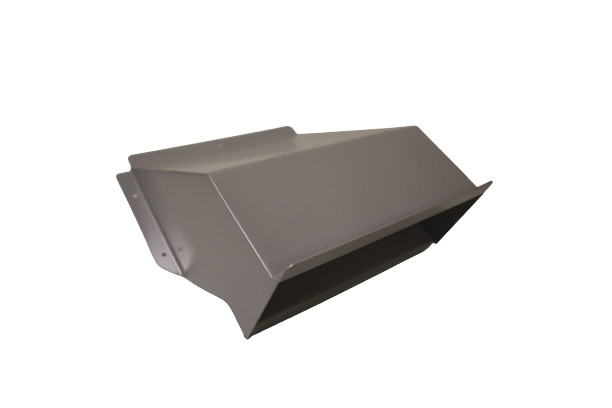

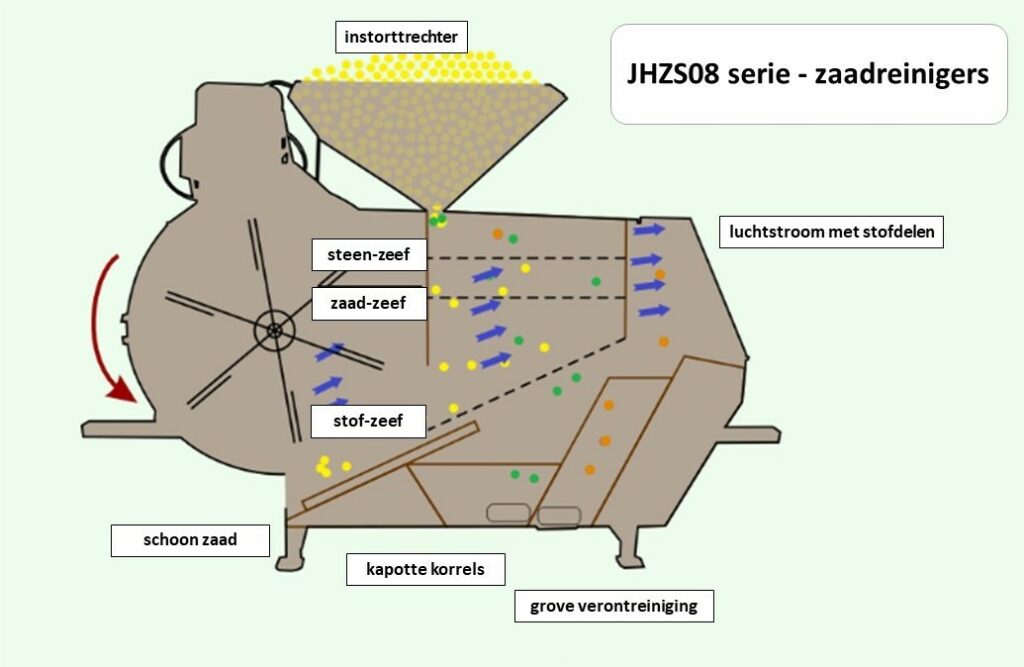

The JHZS08 seed cleaner is based on the ancient principle of a winnowing combined with sieve shaker: “Seperating the chaff from the wheat”. This seed cleaner is constructed extremely simply with a frame of wooden panel that are resonance resistant. From a steel or (optional) stainless steel chute, the grain is distributed tot he first sieve layer seoerating the coarse contamination. In the two subsequent screen layers the finer weed seeds, undersized grains and sand are seperated while a constant air flow blow away light particles. The cleaned grain exits the machine through a central outlet at the rear.

The JHZS08 seed cleaners are intended for e.g. the arable farmer who wants to make his own seed, the organic farmer who wants to clean his crop for animal feed or sale, separating mixed crops such as field beans and wheat or for other target groups. The cleaner is designed for traditional grains as well as special, small, light seeds, flower seeds, grass seeds, vegetable seeds and herb seeds. An added benefit of having a seed cleaner is that the harvest can be accelerated with higher (but contaminated) yields. After harvesting, the cleaner acts as your second combine.

Motor

One or two electric motors are used to drive both the shaking mechanism and the paddle wheel. The standard version uses one 0.5 kW motor with V-belt drive for both the shaking mechanism as the paddle wheel. The special versions use two geared motors that can be controlled in speed via the control box provided. Motor 1 (0.25 kW) is fort he paddle wheel, motor 2 (0.35 kW) is fort he shaking mechanism.

Versions

The JHS800 is the basic version with a single motor and a chute, and sieves made of steel. In the inox/stainless steel versions, chute as well as sieves are made of stainless steel for processing food grade products. The special versions have two geared motors and control box.

Features seed cleaner

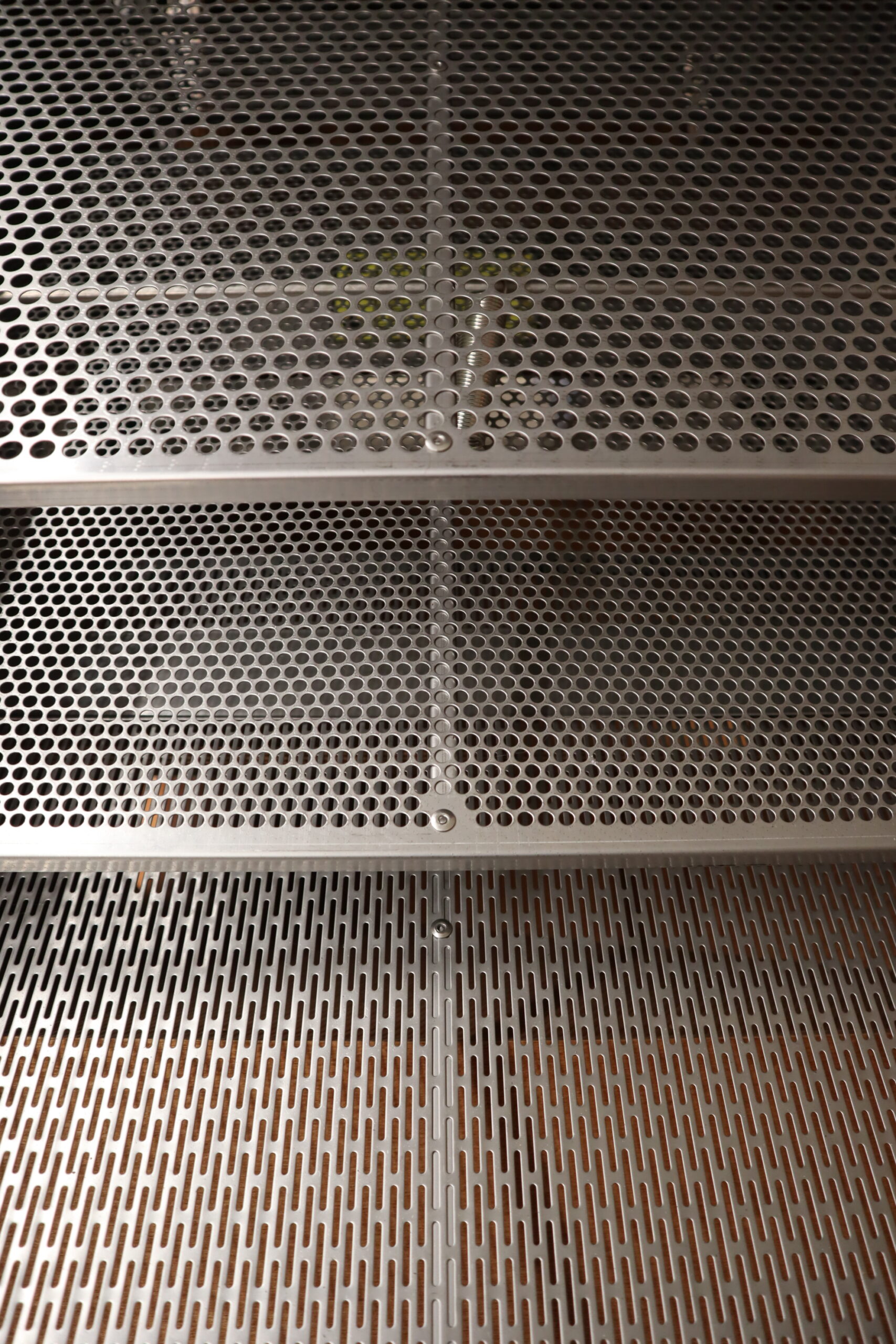

- The machine can be equipped with more than 50 different sizes of perforated (stainless steel) sieves with both round holes and elongated holes.

- Extremely low power consumption

- Simple and transparent control of results

- Sieves are quickly and easily adjusted and replaced

- Requires minimal maintenance

- The average capacity with wheat is 1000-1600 kg per hour

- Each new machine comes standard with 3 sieves of your choice

- CE classification

Overview of available models

| JHZS08 | JHZS08-RVS | JHZS08S | JHZS08S-RVS | |

| Drive | 1 motor | 1 motor | 2 motors Frequency controlled | 2 motors Frequency controlled |

| Adjusted airflow | 4 manual valves | 4 manual valves | Frequency controlled 0-100 % | Frequency controlled 0-100 % |

| Speed sieve decks | Set | Set | Frequency controlled 0-100% | Frequentiegestuurd 0-100% |

| Angle upper sieve | 2 positions | 0-10 degrees | 0-10 degrees | 0-10 degrees |

| Angle middle sieve | 1 position | 0-10 degrees | 0-10 degrees | 0-10 degrees |

| Angle bottom sieve | 2 positions | 3 positions | 2 positions | 3 positions |

| Chute and sieve decks of stainless steel | No | Yes | No | Yes |

| Weight | 115 kg | 130 kg | 140 kg | 140 kg |

Options

The following options are available for the JHZS08 series:

- additional sieves

- Rv – round holes of the sieve

Diameter round holes Ø (mm):

1,5 / 2,0 / 2,5 / 3,0 / 3,5 / 4,0 / 4,5 / 5,0 / 5,5 / 6,0 / 6,5 / 7,0 / 7,5 / 8,0 / 8,5 / 9,0 / 10,0 / 11,0 / 12,0 / 13,0 / 14,0 / 16,0 / 17,0 / 18,0

- Lv – elongated holes of the sieve

Size of slots width/length ≠ (mm):

1.0 x 20 / 1.2 x 20 / 1.4 x 20 / 1.5 x 20 / 1.8 x 20 / 2.0 x 20

/ 2.2 x 20 / 2.4 x 20 / 2.5 x 20 / 2.8 x 20 / 3.0 x 20 / 3.2 x 20 / 3.5 x 20 / 3.8 x 20 / 4.0 x 20 / 4.5 x 20 / 5.0 x 20 / 6.0 x 20 / 7.0 x 20 / 8.0 x 20

- chutes

- cover for the entire machine

Operating principle seed cleaner JHZS08

Video seed cleanerJHZS08